- ECOVADIS SCORING : GOLD 72/100 - Top 1% of best noted companies overall categories.

- French CARSAT (Experts in health and safety standards) highlights our VOC treatment in our smart card bodies’ production unit.

- Work procedures improved by occupational therapist.

Our technical sales team can guide you to the products most suitable for your application, considering your context and your constraints. They can discuss the most appropriate conditions for use, assembly and maintenance, while maintaining competitive prices.

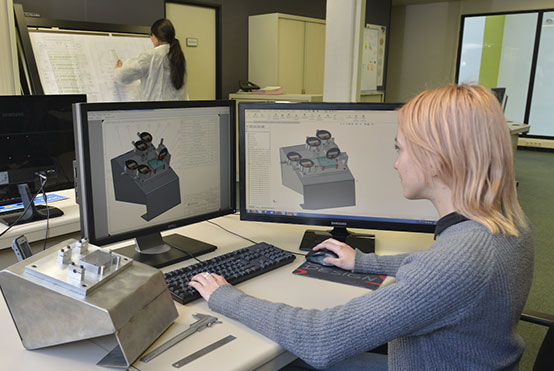

A highly qualified R&D team and the latest and up-to-date techniques :

• CAO – 4 Workstation Catia2D and UG3D

• Plan

• Rheological Study

• Raw materials experts (PEI,PEEK,PC,PU,PA6.6,ABS,PBT, Organic)

• Co injection and bi materials injection experts

Skilled manufacturing teams:

• 3 shifts per day // 7 days a week

• A strongly robotized business unit for higher autonomy competitiveness: 1 operator for 6 lines and 1 technician for the production unit.

• More than 20 resins can be transformed from our hopers (3 production hopers and 2 more available if needed), or in bags (Octabin or 25 Kgs bag).

• 15 to 20 molds installed each week

Skilled manufacturing teams:

• Lean Management: Implementation of Lean 6 sigma to achieve your 100% satisfaction

• Integrated mechanical workshop for early actions and repairs..